Electrical trace heating

THE ALL-IN-ONE SOLUTION.

In addition to frost protection, electrical heating systems are becoming increasingly important for components in industrial processes. For a multitude of products, the respective media temperature must be maintained or heated up in a process-specific manner.

We offer a wide range of electrical trace heating systems for application in domestic use, power plants, chemical plants, petrochemical and refinery plants.

We provide you with the best solution to your specific requirements and demands on the basis of our long-standing experience in the field of thermal insulation. In doing so, interface minimization is an integral part of our work.

Self-limiting heat tapes

(temperature-resistant up to 240°C)

Flexible use for temperature maintenance and anti-freeze protection / applications with continuous operation temperatures from 65°C up to 240°C. They can be tailored according to the component which needs heating on-site!

Teflon-insulated Heating Cable

(temperature-resistant up to 260°C)

Teflon-insulated heating cables are used for bigger areas and pipe lengths. They are very resistant to most chemical influences. These highly flexible heating cables are applicable for continuous operation temperatures up to 260°C and a nominal voltage up to 750V!

Mineral-insolated heating cables

(temperature-resistant up to 1000°C)

Mineral-insolated heating cables are used for applications with more than 260°C operating temperature. Depending on the needed temperature-/corrosion resistance, the cables are manufactured with an outer sheath of CuNi, VA 1.4541 or Inconel. All heating cables and connecting components are also available with a certification for use in hazardous areas.

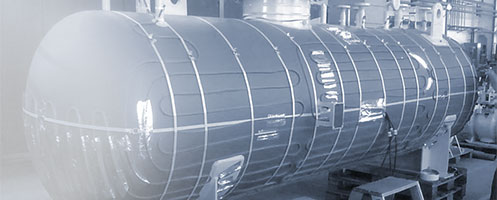

Tank heating with self-limiting heating tape. This application allows for use in explosivehazard areas within permissible temperature class, also without temperature limitation.

Heating of a tubular screw conveyor with mineral-insulated heating cables. Due to the high temperature resistance of these heating cables temperatures of up to 600 °C can be maintained.

We are able to deliver for all heating systems the respective switching and control systems as per customer specifications. Depending on the requirement in simple relay technology up to electronic control with link-up to the respective process control system.